STAINLESS STEEL CONVEYOR ROLLER BASICS AND USES

WHAT IS STAINLESS STEEL?

“Stainless” was a word used in the early development of steels for cutlery applications. It was used as a generic name for the steels used in cutlery manufacturing. It now encompasses a wide range of corrosion resistant grades.

Stainless steels are iron alloys with a minimum of 10.5% chromium. To enhance the structure, corrosion resistance, machinability, formability and strength other alloys are added.

The main objective for stainless steel conveyor rollers is that they are corrosion resistant for a specified application. Since corrosion resistance is not the only consideration, physical and mechanical properties must be considered when specifying a grade of stainless steel.

For corrosion resistant conveyor roller applications, either PVC (plastic) conveyor rollers or stainless conveyor rollers are commonly utilized in the material handling industry. “Stainless” steel is a term used to describe steel that is not affected by corrosive substances.

A variety of stainless steels are available for specific applications with varying degrees of corrosion resistance in conveyor rollers.

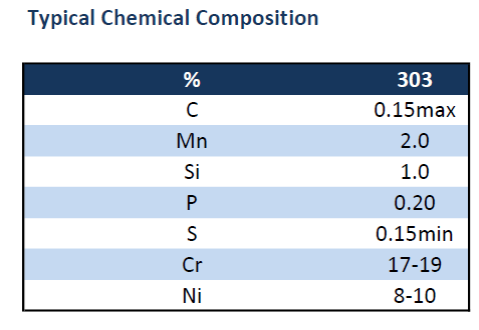

In this article T-303 stainless steel will be discussed as it pertains to corrosion resistant conveyor rollers. This grade of stainless is austenitic and is normally non-magnetic and has high levels of chromium and nickel.

Austenitic Grades:

This group of stainless steel contain the following compounds:

- 17%-25% Chromium

- 8% Nickel

- Other compounds are added to achieve the required properties

Stainless steels are iron alloys with degrees of nickel, molybdenum, titanium and copper. These alloys are combined to give stainless steel its properties. The main objective for stainless steel is corrosion resistance for a specific application. It is important to know the properties of the different stainless grades.

The T-303 stainless steel alloy was developed as a “free machining” grade. This grade has either Sulphur or selenium added to give for excellent machining properties. By adding the “free machining” alloys, T-303 grade of stainless steel is slightly less corrosion resistant than T-304 grade of stainless steel. The addition of Sulphur to T-303 stainless may cause pitting corrosion in certain applications. Corrosion resistance for T-303 stainless remains to be acceptable in mild environments.

1. COST:

The cost of T-303 stainless is slightly higher than T-304 stainless steel, however, due to the added sulfur for machinability, T-303 stainless is not easily welded. T-304 is easier to weld.

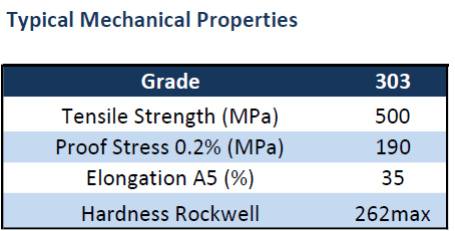

2. DURABILITY:

The properties of stainless steel makes them corrosion resistant. T-303 stainless steel is slightly less corrosion resistant than T-304. T-303 is slightly more corrosion resistant that T-304. In typical conveyor roller applications T-303 stainless is acceptable. Each application should be reviewed to make certain that the stainless.

3. EASE OF USE:

T-303 stainless is not as easy to machine as T-304. However, conveyor rollers do not require extensive amounts of machining. The axle is typically sheared to length and the tube is cut with a saw or rotary cut-off blade. If large amounts of rollers are being machined, it might be better to purchase T-304 stainless grade.

4. WELDING OF T-303 STAINLESS STEEL

Due to the Sulphur in T-303 stainless steel, weldability is poor. For chain driven live roller conveyors, sprockets are welded to the roller tube. If it necessary to use T-303 stainless, the recommended welding electrodes or filler rods are grade T-308L and T-309 stainless. Annealing the welds will result in better corrosion resistance.

5. HEAT RESISTANCE OF T-303 STAINLESS STEEL

The heat resistance of T-303 is good. Carbide precipitation occurs with continuous use at 800 degrees Fahrenheit. Oxidation occurs when T-303 stainless is exposed to continuous use to 1,400 degrees Fahrenheit.

6. DURABILITY:

Stainless steel is corrosion resistant in many conveyor roller applications. Where plastic conveyor rollers do not have the capacity required, stainless is a good alternative.

7. APPLICATIONS:

Stainless conveyor rollers are typically utilized in the following material handling applications:

- Gravity conveyors

- Powered belt conveyors

- Sprocket driven conveyor rollers

- Dishwashing machinery

- Food handling conveyors

- Wash down applications

- Conveyors interfacing with packaging machinery.

The components must meet corrosion resistance in order for the conveyor roller to operate properly under the environment that it will be subjected.

CONSULTATIVE APPROACH:

CSE utilizes a consultative approach to achieve the proper selection of its corrosion resistant conveyor rollers. By consulting with the customer as to the requirements and customer’s objectives, CSE will recommend the proper materials utilized in the corrosion resistant conveyor rollers.

The components must meet corrosion resistance in order for the conveyor roller to operate properly under the environment that it will be subjected.

DISCLAIMER:

Conveyor Systems & Engineering, Inc. (CSE) makes no warranty, representation, or guarantee regarding the information contained herein or the suitability of the information contained herein or its products and services for any particular pupose, nor does CSE assume any liability whatsoever arising out of application or use of any product CSE markets or sells. The products sold hereunder and any other products sold by CSE have been subject to limited testing and should not be used without testing by customer for customer’s specific application. Any performance specifications are believed to be reliable but not verified, and Buyer must conduct and complete all performance and other testing of the products, alone and together with, or installed in, any end-products. Buyer shall not rely on any data and performance specifications or parameters provided by CSE. It is the buyer’s respomsibility to independently determine suitability of any products and to test and verify the same under the conditions that customer intends to use equipment supplied or specified by CSE. The information provided by CSE hereunder is provided “as is, where is” with all faults, and the entire risk associated with such information is entirely with the Buyer. CSE does not grant, explicitly or implicitly, to any party any patent rights, licenses, or any other intellectual property rights, whether with regard to such information itself or anything described by such information. Information provided in this document is proprietary to CSE , and CSE reserves the right to make any changes to the information in this document or to any products and services at any time without notice. This data is indicative only and must not be seen as a substitute for the full specification from which it is drawn. In particular, the mechanical property requirements vary widely with temper, product and product dimensions. The information is based on our present knowledge and is given in good faith. However, no liability will be accepted by CSE in respect of any action taken by any third party in reliance thereon. As the product(s) detailed may be used for a wide variety of purposes and as CSE has no control over their use; CSE specifically excludes all conditions or warranties expressed or implied by statute or otherwise as to dimensions, properties and/or fitness for any particular purpose. Any advice given by CSE or its personnel to any third party is given for that party’s assistance only and without liability on the part pf CSE. Any contract between CSE and a customer will be subject to CSE’s Condition of Sale. The extent of CSE’s liabilities to any customer is clearly set out in those Conditios; a copy of which is available on request.